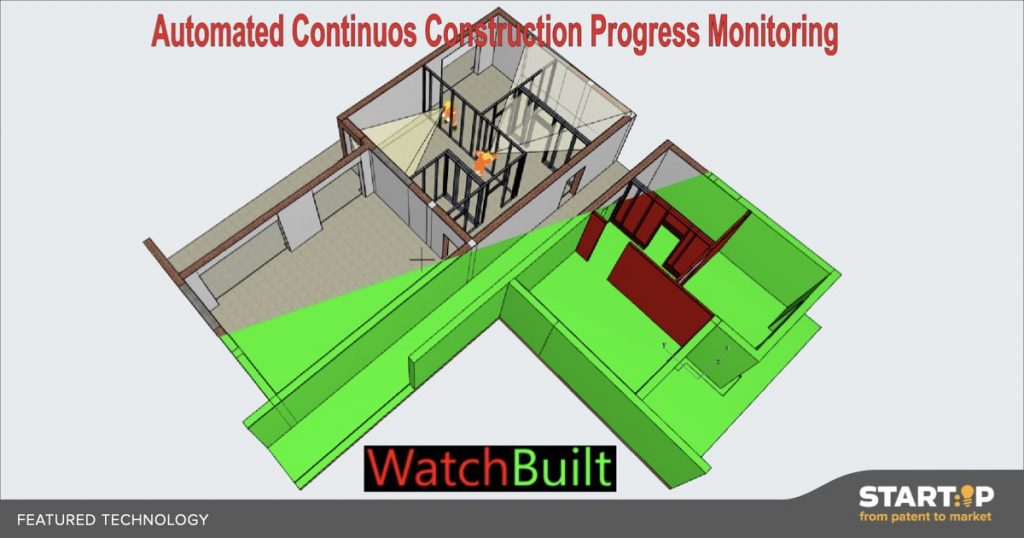

Tracking construction progress is a vital task. When performed manually, it is inefficient, and the risk for mistakes and delays in the project increases. This technology automates construction site monitoring with smart 3D-scanning helmets and software that, together, generate a 3D model that can be continuously compared with the original design.

START:IP

Technology Abstract

Smart Continuous Construction Site Monitoring

Smart helmets and software for continuous construction monitoring

Bookmark1

The technology consists of two parts – the smart helmets, worn by construction workers on-site, and the 3D model-building software. The smart helmet is fitted with a 3D depth camera and spatial sensor. As construction site workers go about their tasks, the camera collects visual information at regular intervals, generating so-called “point clouds” of data. These point clouds are fed through to the software that calibrates and generates a 3D model. This model is compared to the 3D Building Information Model (BIM), and thereby identifies which parts have been completed, what is yet to be done, and any potential errors in the construction. The critical advantage of the technology is the ability to continuously be up to date on the building progress. Currently, such detailed inspection could only occur, at best, once per week, and manually as opposed to being fully automated. The net result is a more efficiently managed building project, preventing mistakes and keeping the project on time.

If you click the button and fill out the form to be “matched” with a technology, we will introduce you to the scientist / transfer manager of the respective research institution. In this way, you immediately have the chance to receive more detailed information and to start discussions about a possible joint project.