Electrodeposition is the process of coating surfaces using electrochemical reactions, for example to prevent corrosion, improve aesthetics, or create an electronically conductive surface. Current standard methods for electrodeposition are resource-intensive and costly. This technology solves these problems, enabling nanoscale-thin electrodeposition on a variety of surfaces.

START:IP

Technologie Kurzbeschreibung (nur Englisch)

Improved Thin Layer Deposition

Efficient method for thin layer photo- and electro-deposition

Bookmark1

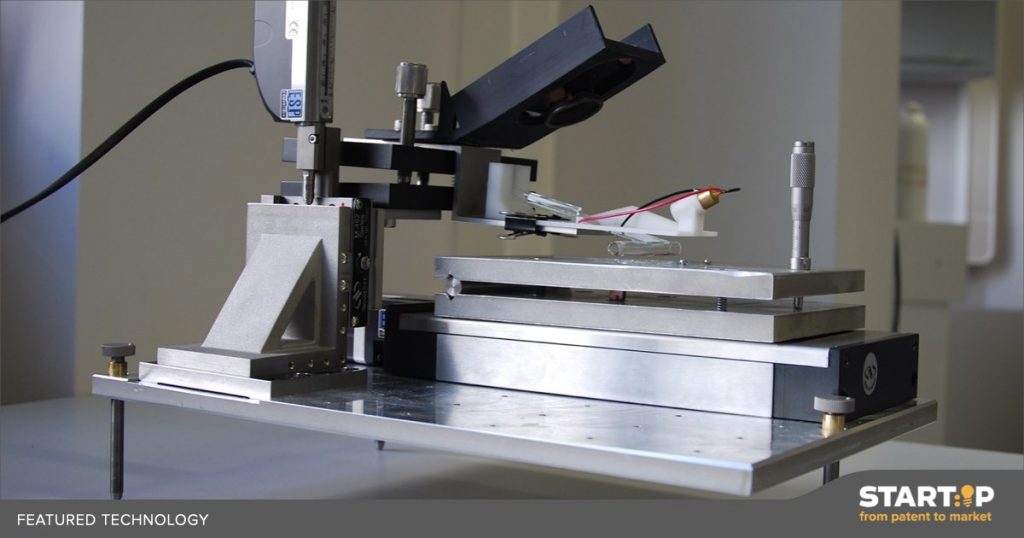

Normally, photo- or electrodeposition is performed using very large volumes of liquid solution containing reactive precursors, to which an electric current or light is applied to catalyze a chemical reaction that leaves the reaction products on the surface. The novelty of this technology is that it can print various materials onto surfaces using a thin meniscus of this liquid instead. The meniscus, formed between a bar and the surface to be printed on, is a much smaller volume, thereby reducing costs and waste, but also enabling greater precision in what is being printed. In order to cover a large area, the meniscus is moved and an electric voltage is applied between the bar and the surface in order to induce electrochemical reactions. Alternatively, focused laser beam is directed on the meniscus in order to induce photo-chemical reactions. This greater control can print very precisely, in thin layers down to the nanoscale. The device can be used to print on virtually any kind of material for the surface, including flexible surfaces which can be used in roll-to-roll applications, which in particular is gaining interest for flexible plastic solar cells. Speaking of which, one can print plastic polymers, such as the ones used to make organic solar cells. Such solar energy technology is of great interest, not only because of increased demand for green energy solutions, but because these cells are much cheaper to produce than those made using silicon. By changing the voltage applied to the printer bar, these researchers have found that they can manipulate the structure of these polymers as they are deposited on the surface, which has exciting potential for increasing the efficiency of the solar cells. In summary, this novel printing technology can print metal oxides, metals and non-metals onto a variety of surfaces, in a very precise and resource-efficient manner.

If you click the button and fill out the form to be „matched“ with a technology, we will introduce you to the scientist / transfer manager of the respective research institution. In this way, you immediately have the chance to receive more detailed information and to start discussions about a possible joint project.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren